The recent saltwater well blowout in Crane County Texas south of Odessa this past January of 2022 highlighted the issues that can occur with underground injection wells. While these types of problems are rare, it is important to understand how these types of wells are regulated. Also, from a mineral owner perspective, it is important to understand who benefits from underground injection wells used in the oil & gas industry. In this episode, we talk about the different types of injection wells and considerations from both a surface and mineral owner perspective.

Be sure to also subscribe on Apple Podcasts via the link above and please leave us an honest rating and review. We read every one of them and sincerely appreciate any feedback you have. To ask us a question to be featured on an upcoming episode, please leave a comment below or send an email to feedback@mineralrightspodcast.com.

Different Types of Injection Wells and What They are Used for

First of all, the EPA regulates the construction, operation, permitting, and closure of injection wells used to place fluids underground for storage or disposal.

An injection well is defined as a well that is used to place fluid underground into porous geologic formations. These underground formations may range from deep sandstone or limestone, to a shallow soil layer. Injected fluids may include water, wastewater, salt water, or water mixed with chemicals.

Classes of injection wells. The federal government outlines injection well requirements in the Underground Injection Control (UIC) regulations at 40 CFR 144.3.

One of the primary purposes of the UIC program is protecting underground sources of drinking water or USDW’s). Regulations prohibit injecting fluids into these USDW’s.

The Underground Injection Control program consists of six classes of injection wells. Each well class is based on the type and depth of the injection activity, and the potential for that injection activity to result in endangerment of a drinking water source. A few notable ones include:

- Class I wells are used to inject hazardous and non-hazardous wastes into deep, isolated rock formations.

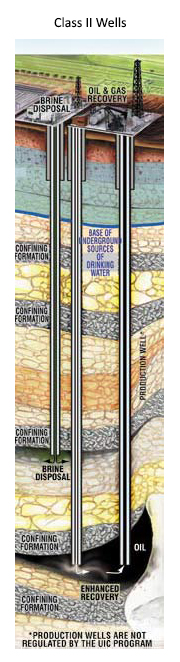

- Class II wells are used exclusively to inject fluids associated with oil and natural gas production. This includes Saltwater Disposal Wells, Enhanced oil recovery wells, and petroleum storage wells

- Class III wells are used to inject fluids to dissolve and extract minerals. These are wells that are used to solution mine minerals located underground.

- Class IV wells are shallow wells used to inject hazardous or radioactive wastes into or above a geologic formation that contains a USDW.

- Class V wells are used to inject non-hazardous fluids underground. Most Class V wells are used to dispose of wastes into or above underground sources of drinking water. – Geothermal electric power wells fall under this class

- Class VI wells are wells used for injection of carbon dioxide (CO2) into underground subsurface rock formations for long-term storage, or geologic sequestration. (used for carbon capture and sequestration or CCS)

Oil and gas Injection Wells

These are often called Saltwater Disposal Wells or SWD’s. They are one type of Class II injection wells which are oil and gas related:

The two other categories of injection wells that are oil and gas related are enhanced oil recovery wells and hydrocarbon storage wells.

- Saltwater Disposal wells are used to deal with produced water, in other words, the water that is produced along side any oil, natural gas, or natural gas liquids from an oil or natural gas well. While some produced water can be treated and re-used for things like completing new wells, many times it is less expensive to treat and dispose of it by reinjecting into an underground formation that is similar to where it came from. We talked about Saltwater Disposal Wells and agreements covering these types of wells in Episode 83 so be sure to listen to that one if you want to learn more about them. Today we’re going to focus on the other types of disposal wells.

- Enhanced recovery wells are wells that go down into oil bearing formations to recover additional hydrocarbons from the formation. These may be wells that previously produced oil & gas but that were converted to an enhanced recovery injection well to help boost production from a declining oil field. In some cases, the operator may drill a new injection well that is specifically designed for injecting fluids into the formation.

Finally, the other type of Class II well is a hydrocarbon storage wells. These are not very common and the best example of these are the wells that are used to store oil into underground salt caverns as part of the U.S. Strategic Petroleum Reserve. There are only a few hundred of these in the U.S.

Other Types of Injection Wells?

There are several other classes of injection wells and we’ll highlight a few notable ones:

Class III Wells are used in mining substances like uranium, salt like nacolite (sodium bicarbonate), copper, and sulfur. In fact, the majority of salt and uranium mining occurs through in-situ leaching or solution mining using these types of wells.

The way this works is the company drills injection wells into the formation containing the substance they want to mine (like uranium or sodium bicarbonate)

A solution is injected into the well into the formation and it is allowed to remain in contact with the formation for enough time to dissolve the substance they are going after.

Once it is saturated, they bring the brine up to the surface through a production well where they separate out the salt or uranium or other substance and then re-inject the solution back into the formation to extract more minerals.

An interesting thing to note is that companies are required to extract more fluid than is injected to prevent the injected solution from leaving the mining area and contaminating any drinking water.

Are all Injection Wells Deep?

Injection wells can be of varying depth and the required depth is dependant on the formation that is being injected into and the type of well. Injection well construction is based on the type and depth of the fluid injected. For example, wells that inject hazardous wastes or carbon dioxide (CO2) into deep isolated formations have sophisticated construction. These wells are designed to provide multiple layers of protective casing and cement. In contrast, shallow wells are usually of simple construction.

Here are some examples:

Class VI wells that inject CO2 underground for permanent storage as in the case of Carbon Capture and Sequestration or CCS, these wells are usually very deep.

On the other hand, a class I well dealing with non-hazardous waste, are allowed to inject far below the lowermost USDW. So if sources of drinking water are in shallow formation, you might have an injection zone as shallow as say 2000 ft but if there are deep drinking water aquifers, then you could have wells that are 10,000 ft in depth or more.

All types of injection wells required both EPA UIC permits as well as state and local permits that take into account things like siting, construction, operator, monitoring and testing, reporting, recordkeeping, and eventually closure or plugging of these types of wells.

- EOR vs. water storage

- Co2 Sequestration

- Solution mining (roundtrip)

Who Gets Paid For Injection Wells?

The short answer is it depends. For Saltwater Disposal Wells there are agreements that cover compensating the landowner for the use of their lands for these types of disposal wells. Again, we covered this in detail in Episode 83 so be sure to listen to that episode for more information.

From the mineral owner perspective, however, we don’t usually get compensation from the operation of a disposal well. Of course, it depends on the language in your oil and gas lease but if your lease has language such as “and the exclusive right to inject air, gas, water, brine and other fluids from any source into the subsurface strata, and any and all other rights and privileges necessary, incident to, or convenient for the economical operation of said land”, then the operator could potentially convert an oil or gas well into an injection well and dispose of fluids from your wells as well as potentially fluids from other lands as well. This lease language allows the operator to operate the injection well and not pay the mineral owner for this particular usage.

Now, if an injection well is used in the process of solution mining for an underground mineral like sodium bicarbonate or uranium, then while you might not get compensated directly from the operation of the injection well, you should get compensated for the production and sale of the extracted minerals.

Again as mentioned in previous episodes, the surface owner would likely be the one that is approached to sign a saltwater disposal well agreement but in many cases it is likely easier and more cost effective for them to just purchase a tract of land for these purposes.

Resources Mentioned in This Episode

Thanks for Listening!

To share your thoughts:

- Leave a comment or question below (we read each one and your question may be featured in a future episode)!

- Ask a question or leave us feedback via email.

To help out the show:

Click the Apple Podcasts Logo Above to leave us a rating & review. It really helps us reach those that need to hear this information and only takes a minute. We greatly appreciate it! Plus, you can get a shout out on a future episode!

Thanks again – until next time!